surgical steel

The watchmaking city of Biel is home to the watchmaking and medical industry, which uses the latest steel alloys. sknfie uses the latest surgical steel, in which carbon is replaced by nitrogen, which increases corrosion resistance by a factor of 4. This makes sknife knives ideal for use at sea. The high hardness of 58 HRC (range of Japanese knives) also means the knife stays sharp for a long time.

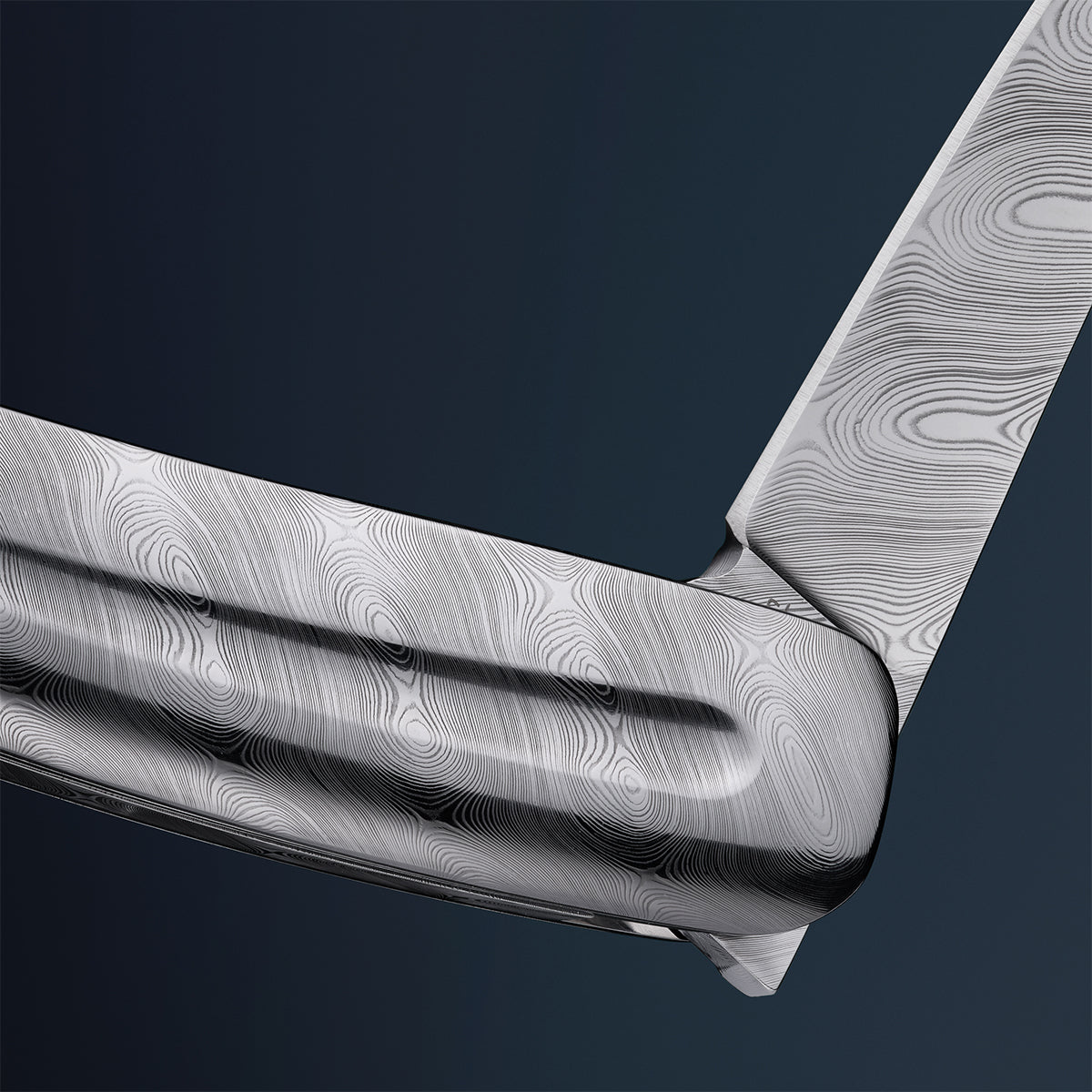

damask

For both the pocket knife and the Damascus cutlery, we work with a corrosion-resistant torsion Damascus steel from Damasteel, which is forged from two high-quality knife steels. The beautiful structure only becomes apparent through etching.

We achieve over 1,000 layers in our steak cutlery, 800 in our pocket knives with wooden handles and over 1,600 layers in our pocket knives in full Damascus steel.

SUSTAINABILITY

Sustainable products & services - our products are used every day in top gastronomy. Thanks to our innovative materials (surgical steel and stabilized wood), we now expect a service life of over 30 years. We work exclusively with wood from the region and are "SWISS WOOD" certified. Swiss wood certification has higher sustainability standards than FSC.

Resource efficiency & circular economy - our products are made by hand on grinding machines specially made for us, which means they are produced in a resource-saving manner and with almost no waste. We deliver our products in wooden and cardboard packaging and ship everything plastic-free. Waste is separated and recycled to ensure proper disposal and maximize resource recovery. We were the first company in Switzerland to use grass paper for all documents. Grass paper requires 8x less energy to produce.

Reducing the carbon footprint - we mostly use the train for travel and have been driving electric cars for years.

Sustainable supply chains - we work regionally with family businesses and thus avoid long transport routes.

Employee engagement & corporate culture - we offer flexible working models such as part-time and home office. We also offer jobs for people with disabilities and work closely with support workshops in the region.

Schweizerholz

Swiss wood: the walnut wood and the ash wood with a beautiful wood structure come from a wood turning workshop in Emmental (Swiss wood, FSC-certified). To make the wood durable, it is 100% stabilized under vacuum and pressure. The color can also be changed by adding color. This technology is based on the latest research results from development projects with the "Höhere Fachschule Holz" in Biel. The packaging is also made from steamed Swiss fir wood.

Label Schweizer Holz

The “Swiss Wood” label guarantees the following core principles:

1. Sustainable forest management

2. Controlled supply and processing chain

sknife (DE) Certificate «Label Schweizer Holz»

sknife (FR) Certificate «Label Swiss Wood»

sknife (EN) Certificate «Label Swiss Wood»

From Tree Trunk to Knife Handle

Stabilized Swiss wood

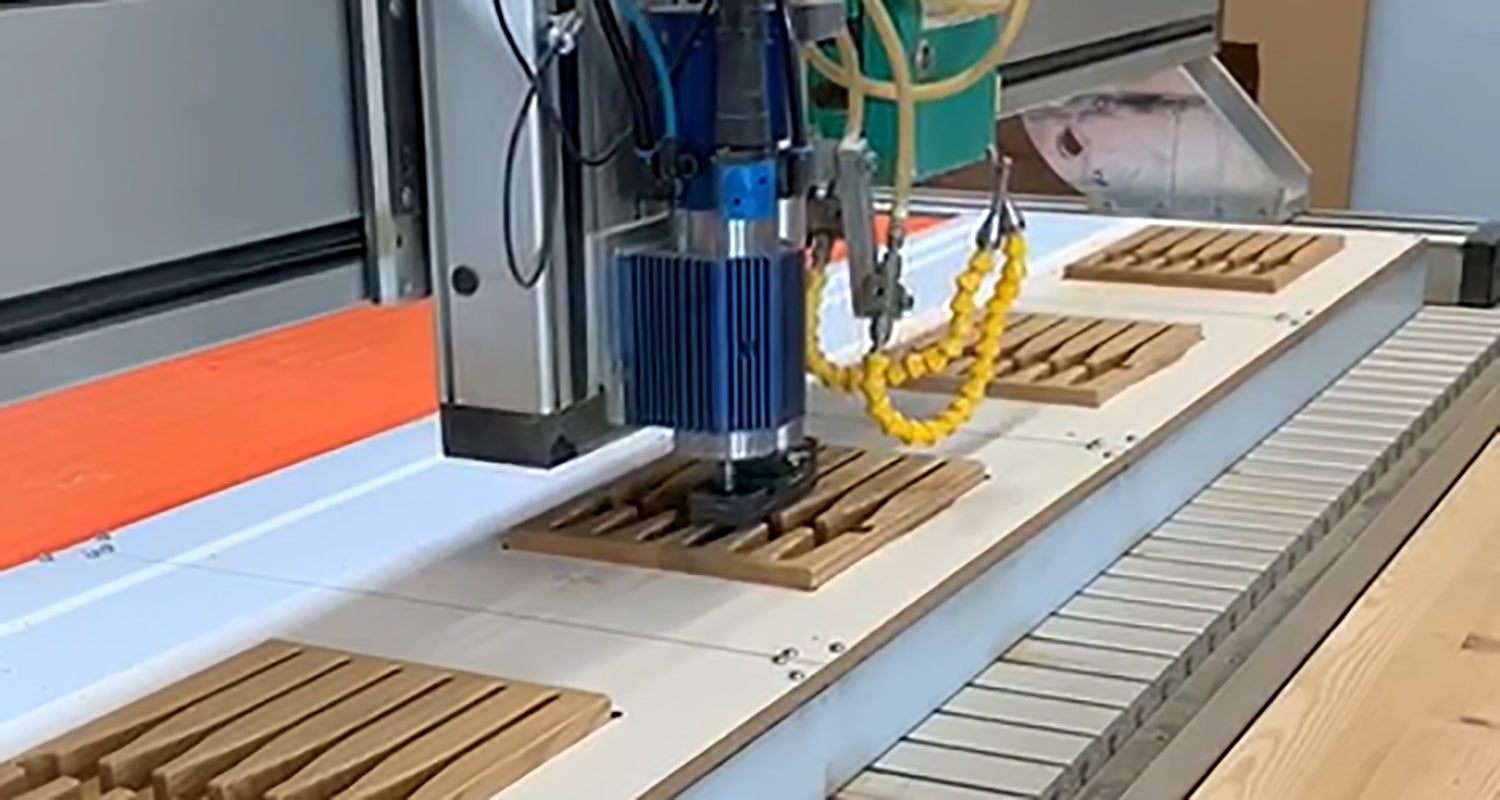

Shaping stabilized Swiss wood

milling handle scales

Sustainable packaging of sknife knives

milling wooden boxes